Data-driven design

New, advanced methodologies for footwear design and manufacturing have come out of a concept called Evolve IM, run by London-based designer Assa Ashuach.

Digital design specialist Assa Ashuach has started to share details of a collaborative footwear project that he has led. It forms part of a wider European Union-funded research programme called Re-FREAM, in which artists, scientists and designers have worked together with the aim of rethinking manufacturing processes for the whole of the fashion industry, including shoes.

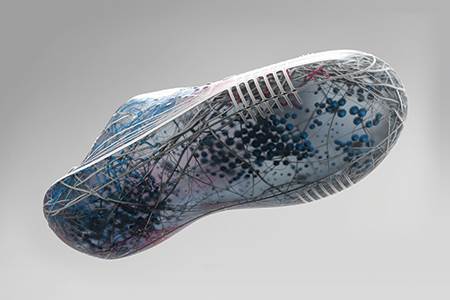

Assa Ashuach’s contribution has taken him on an exploration of new materials and fabrication methods, resulting in what he calls a more sustainable approach and a wearable, user-centred design. A new “biometric evolutionary shoe”, the Evolve IM, is the product to have come out of this.

It uses embedded, 3D-printed sensor technology which can collect the biometric data of the wearer of the shoe. Other technology it uses includes thousands of gel particles of different densities, produced by polymer 3D printing solutions specialist Sratasys, and these, too, can capture information, in this case details of how the shoe works when it is worn. The value of all this, according to Mr Ashuach, is that data from each wearer can go directly into the Cloud to help footwear designers and manufacturers make improvements when the time comes to produce new versions of their shoes.

He explains that this, in essence, is what he means when he refers to the footwear as “evolutionary”. He talks of a new evolutionary approach to design in general. “The basic proposition is that the first generation of a product will learn so as to improve the second generation,” he explains. “Objects have sensors built in and they, the sensors, learn. They study use over a period of time so that products can improve themselves.”

Optimised by nature

In this scenario, objects, such as shoes, will no longer be “living in isolation”, as Assa Ashuach puts it, but will instead be part of an ecosystem. Its adaptability to change that enables survival, he says, tipping his hat to Charles Darwin. “Bamboo learns as it grows; it has a certain form of bio-intelligence,” he insists, adding that the same is true of leather, which he describes as “a fascinating, probably unbeatable material” that has been growing on animals for thousands of years and is, therefore “optimised by nature”. Looking at kangaroo leather through a microscope is, he claims, like looking at cashmere.

Working on Evolve IM led Mr Ashuach to study footwear and feet quite intensely. “It’s not my natural habitat,” he admits. “I worked with Nike for many years, but more in research and innovation.” Something that has fascinated him is the discovery that “we cannot just virtualise everything”. Looking at lasts helped him see the importance of human wisdom too and to produce a shoe that is “a dialogue between the physical and virtual”. The gel particles provide a good example of this because, as well as providing data to help improve new versions of the shoe, they have an immediate, physical role in the here and now too. They are there to provide cushioning in the shoe. And because they have fluidity, they can provide bespoke cushioning for each foot.

Health concerns

Seeing this work provided the designer with what he calls “a moment of joy”. His first thought had been to create air bubbles for this function, but this proved too difficult, because of “machine constraints”. He then began to think about filling the midsole of the shoe with liquid, but decided this would be too difficult too. “We started to play with the chemistry,” he explains, “and found material that could do what we wanted in gel form. We used it to create this new midsole that reads pressure distribution under your foot.” He has visions of this leading to a new system for podiatrists to use because it would be possible to integrate the Evolve IM or a future shoe using similar technology into a system to alert medical professionals if a vulnerable person’s weight changes or if pressure points on the foot or excess humidity there look likely to become health concerns.

Colourful celebration

For his next innovation, he turned to 3D printing on fabric, designing colour-changing particles with different shapes integrated into the fabric of the shoe’s upper. He created scripts to run through hundreds of different colour combinations randomly, based on “certain trigger points” before choosing the one he liked best. What he calls the white skeleton on the upper, which looks a bit like piped icing on a birthday cake, is conductive. “I was trying to celebrate the new technologies we have,” he remarks. The sensors are visible and you can even see the gel particles underneath.

Mr Ashuach explains that the Evolve IM consists of only two parts, a support-free bottom and a flat upper that moves into place and take shape during an assembly process that he insists could be carried out in any location by a small team of people. This ties in with Re-FREAM, which has the stated aim of making fashion manufacturing something that can happen once again in towns and cities across Europe and anywhere else in the most advanced economies of the world. Specifically, though, the wider project supported research in three European hubs focusing on ideas to support the main objectives. The three hubs are Linz, Berlin and Valencia. Urban production of fashion using additive manufacturing, electronics and innovative materials can “create a new value chain for the fashion industry”, the Re-FREAM team says.

Prototype shoes from Assa Ashuach are ready to be part of this and, perhaps unsurprisingly, work is also under way in his studio to develop follow-up versions that he will produce in the near future. The studio’s connection to the Linz hub in particular has already born considerable fruit. How much impact Mr Ashuach’s ideas will make on mainstream footwear production remains to be seen but no one could accuse him of being anything other than broad in his experiments and thoughtful and creative in what he has managed to produce so far.