Shapemode digitally alters elastic fabric with 3D printing process

27/11/2019

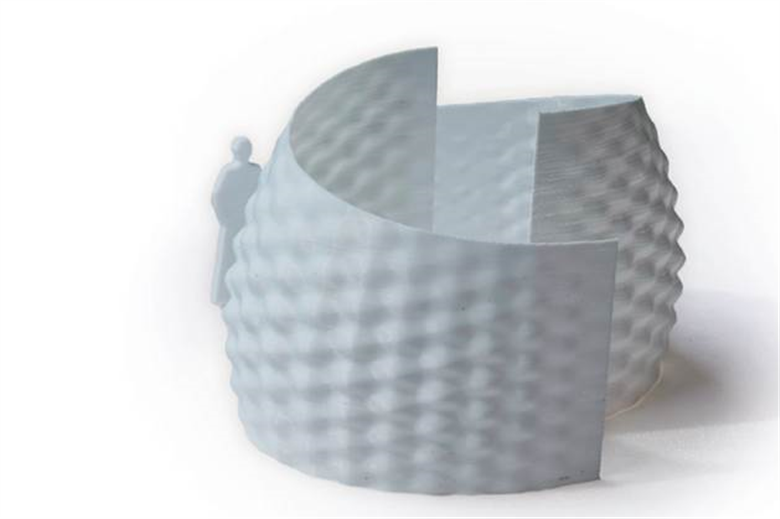

Shapemode described the project, called Sikka (pictured), as “a light architecture composed of modular elements inspired by the shape of the sail, which can take different forms, with the possibility of creating different environments”.

Each is composed of a textile surface, a polymeric structure and a composite superstructure, according to the company. The complex curvature of the surfaces is reached through selective tensioning of the fabric and was realised with a WASP 3MT pellet 3D printer on stretch fabric.

The prototype was made by Timothy Liddell, Mahsa Bohlooli Zamani, Beatrice Capucilli and Leonardo Di Martino, a team of architects and designers from the Polytechnic and the NUMEN Institute.

Sikka was presented at the HOMI 2019 fair in Milan, as part of the Design Competition 2019’s “call for ideas”, which was promoted by the Lombardia Regional administration and the Chamber of Commerce, and coordinated by Milan’s Polytechnic University.

Along with other winning entries, Sikka will be exhibited at Expo Dubai from October 2020 to April 2021 and, before that, at other national events focusing on design.