Footwear automation boost from new Covestro idea

Polymer producer Covestro has announced that hot-melt adhesives based on its Desmomelt U thermoplastic raw material powder can now be applied automatically and in precise doses using digital printing.

It said the development would help footwear manufacturers increase automation in their factories. “Polyurethane dispersions have proved their worth in adhesives for manual shoe production,” Covestro said, “but attempts to automate manual applications with robot-assisted processes have not been successful to date.”

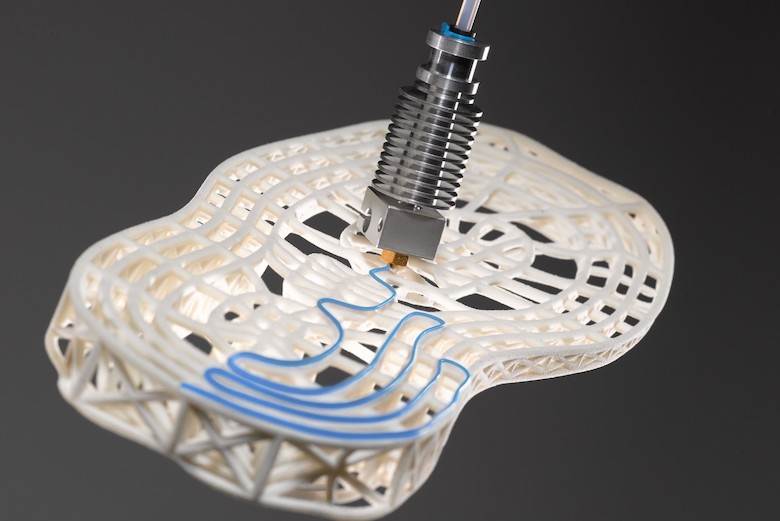

It explained that digital printing, on the other hand, enables shoe manufacturers to automate adhesive application “to the highest level of precision”. Processing steps can be saved and digital application creates less waste.

The manufacture of sneakers and sports shoes is labour-intensive, Covestro said, involving numerous production steps, many of which, including the application of adhesive, are often still performed manually. It explained that bonding the upper material and the outsole requires exact dosing and precise application at the correct location so that the sole does not come off.

It insisted that the digital application of high molecular-weight hot-melt adhesives can provide a good solution for footwear producers.