Win-win: On partnership turns carbon emissions into footwear foam

10/11/2021

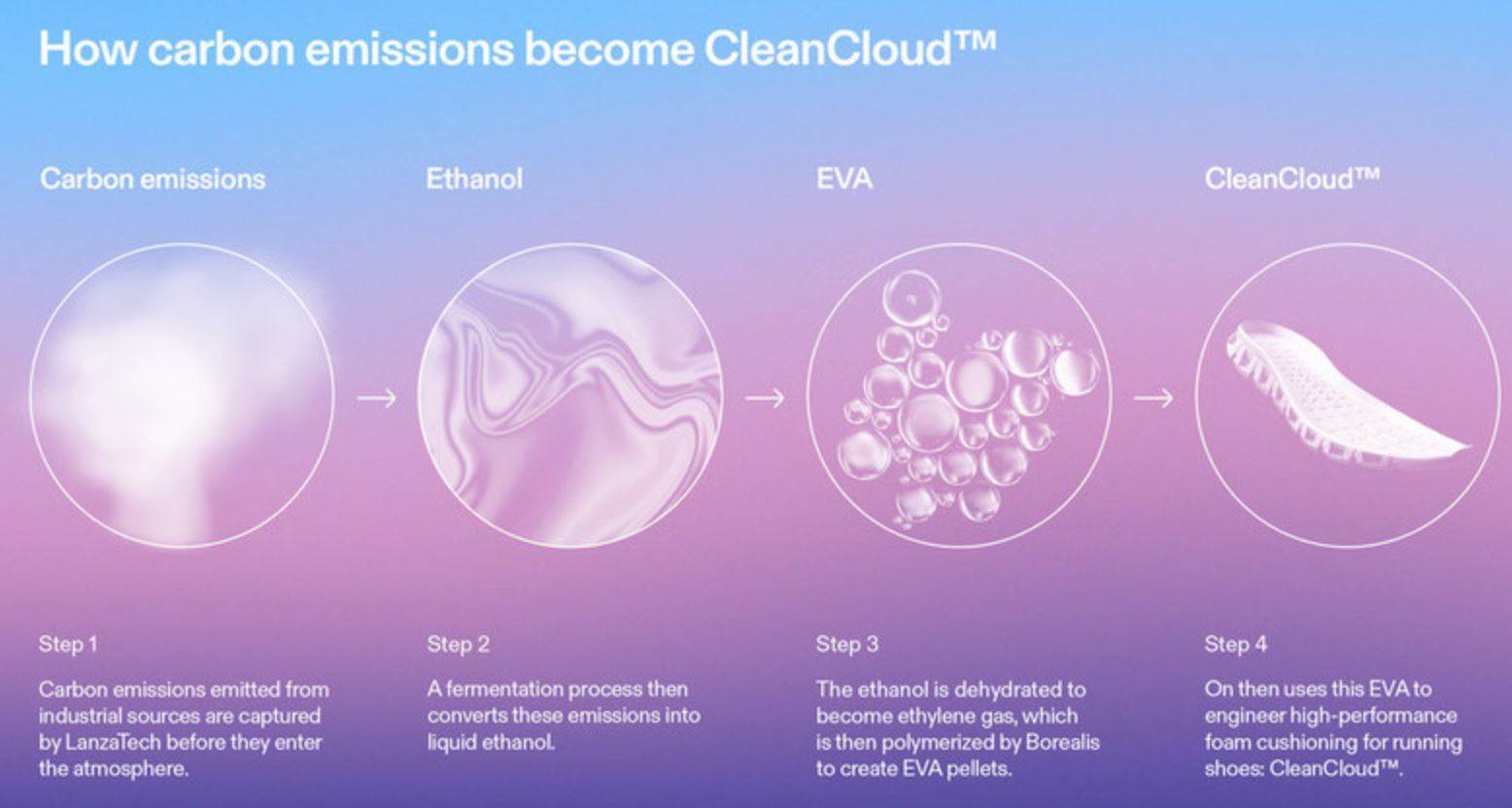

The trio have launched CleanCloud, a foam material made from EVA foam, made using carbon emissions as a primary raw material.

Technology from LanzaTech captures carbon monoxide emitted from industrial sources like steel mills or emissions from landfill sites before being released into the atmosphere. Once captured, these emissions enter a fermentation process. The carbon-rich gas ferments naturally and is converted to liquid ethanol by the bacteria. The ethanol is then dehydrated to create ethylene, which is polymerised by Borealis to become EVA (a copolymer of ethylene vinyl acetate) – the versatile and lightweight material that On works with to create a performance foam for shoes.

On has expressed a desire to move away from petroleum-based resources and has spent four years researching and developing CleanCloud.

Caspar Coppetti, co-founder of On, said: "It's a win-win situation: we are capturing emissions before they pollute our atmosphere and are at the same time moving away from fossil-based materials.”

LanzaTech uses combination of genetic engineering, artificial intelligence, and innovations in mechanical and chemical engineering to manufacture chemicals using a process that soaks up carbon rather than emitting it.

"We are showing the world what is possible when we rethink how we source, use and dispose of carbon," says Jennifer Holmgren, CEO of LanzaTech. "By converting pollution to products, we can see that someday everything in our daily lives will come from recycled carbon. We are excited to be on this journey with On and Borealis to bend the carbon curve, keep our skies blue, and create a sustainable future for all."

Borealis is a provider of advanced plastic solutions essential in creating the EVA foam for CleanCloud.

Lucrèce Foufopoulos, Borealis executive vice-president of polyolefins, innovation and circular economy solutions, said: "With our creative partners On and Lanzatech, we are proud to co-create circularity in carbon, and decouple plastic from its reliance on fossil-feedstock. Through innovation and collaboration, we continue re-inventing for more sustainable living."