EPFL team discovers ‘much simpler’ bioplastic

Research conducted by scientists at the Swiss Federeal Institute of Technology Lausanne, also known as the École Polytechnique Fédérale de Lausanne (EPFL), has resulted in a “new” plastic derived from non-edible plant material or lignocellulosic biomass.

The study was published in scientific journal Nature Chemistry in late June.

Led by Professor Jeremy Luterbacher, the team found that the plastic’s properties are “similar” to polyethylene terephthalate (PET).

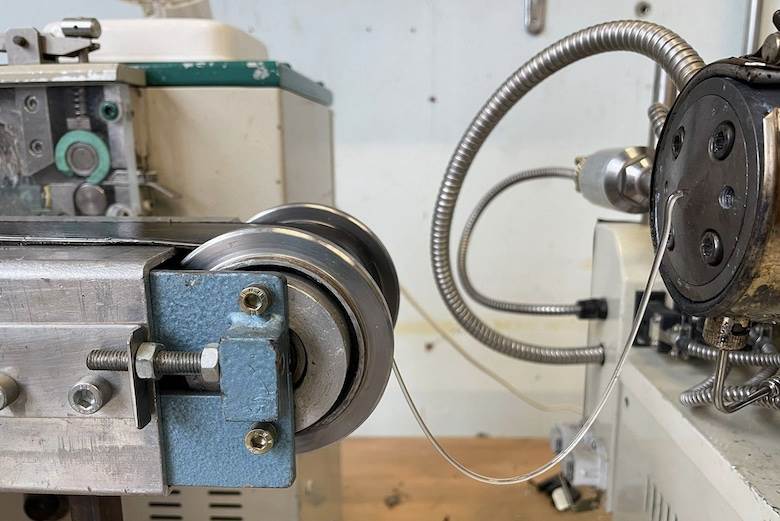

Consequently, the researchers have been able to develop fibres suitable for textile and clothing, as well as filaments for 3D printing and films for packaging.

With funding from the Swiss National Science Foundation, the European Research Council’s Horizon 2020 programme and the Swiss Commission for Technology and Innovation, alongside additional EPFL financing, the study was inspired by an earlier discovery by Professor Luterbacher, published in the journal Science in 2016.

Back then, the professor found that the organic polymer lignin – responsible for giving plant elements such as wood and bark their rigidity – could be turned into a biofuel source by adding formaldehyde, which helps to break lignin apart. This time around, the team repurposed the same chemistry, but used a different aldehyde.

“By using glyoxylic acid instead of formaldehyde, we could simply clip ‘sticky’ groups onto both sides of the sugar molecules, which then allows them to act as plastic building blocks,” said the study’s first author, EPFL doctorial assistant Lorenz Manker. “Using this simple technique, we are able to convert up to 25% of the weight of agricultural waste, or 95% of purified sugar, into plastic.”

Professor Luterbacher added: “By keeping the sugar structure intact within the molecular structure of the plastic, the chemistry is much simpler than current alternatives. This makes it incredibly easy to make, because you don’t have to modify what nature gives you. [It is also] simple to degrade, because it can go back to a molecule that is already abundant in nature.”

Extrusion of the bioplastic to make fibres suitable for 3D printing. Credit: Maxime Hedou.