'Huge possibilites' for novel fabric handle tester

UK-based textiles Roaches International has created a machine which it claims addresses a challenge faced by designers and manufacturers: that of describing and sharing information about fabric aesthetics before manufacturing, without transporting physical samples.

The concept of ‘fabric handle’ – the tactile sensation experienced when touching and manipulating fabric – is a critical aspect of textile evaluation, but is subjective.

Roaches International MD Sean O’Neill said: “No two people will describe how a fabric feels in the same way and the lack of a common language to describe fabric tactility poses communication challenges across the complex global fashion and textile supply chain. How do you objectively measure qualities like softness, smoothness, drape and stiffness?”

Roaches worked with the University of Leeds to develop its new finished fabric evaluation system which defines the tactile properties of fabrics via a haptic spatial system – similar, for example, to the way colour charts are digitally defined for colour palettes, or Tog values rate warmth, said the company.

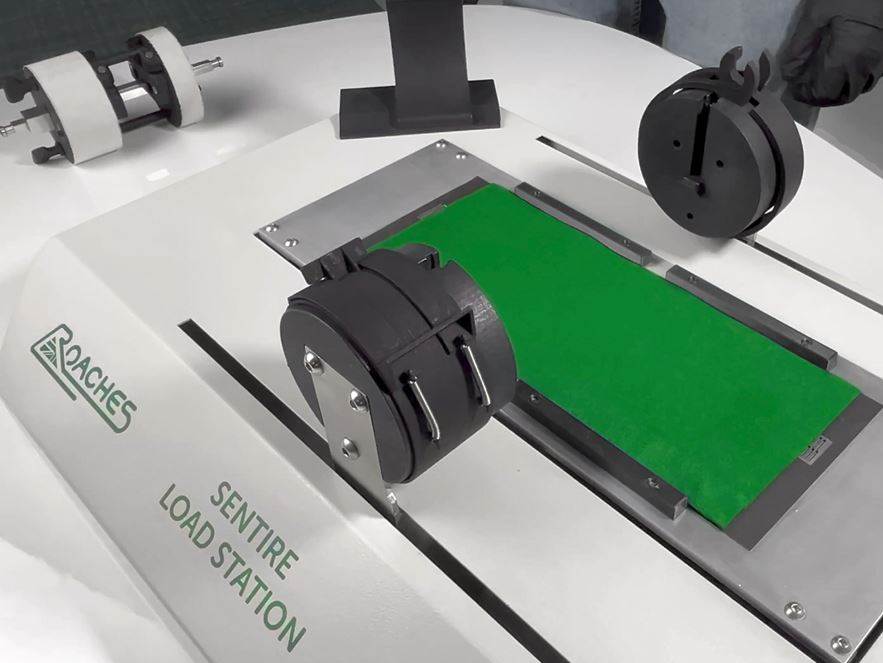

Fabric samples are placed into the Sentire to run a series of tests which generate quantitative fabric tactile property data akin to a fingerprint for the fabric, which can then be compared against other samples and communicated digitally to partners in different locations.

“This technology has the potential to impact the supply chain in a similar way to the spectrophotometer for the communication of colour,” added O’Neill. “We have had a fantastic initial response to the Sentire and its possibilities are huge. Not only can it be used to compare textile tactility globally, but we are also seeing interest from online retailers who want to accurately display the way a particular fabric drapes on the body.”

The precise detection of defects during the production of fabrics has meanwhile been advanced with the introduction of the latest WebSpector automated fabric inspection system by Shelton Vision, another member of the British Textile Machinery Association (BTMA).

Shelton’s patent-pending image processing techniques now recognise and adapt to complex patterns such as camouflage and even on fabrics with significant distortion and deformation. WebSpector systems have already been supplied to manufacturers of performance wear and high-end fashion, automotive interiors and denim.

Martindale testing needs little introduction to textile manufacturers, being well established as the industry standard for abrasion and pilling testing since its initial development and introduction by James Heal back in the 1940s. For 2025, however, James Heal’s development team have taken a fresh look at this classic instrument and the result is the new Martindale Motion. This redesigned nine-station Martindale instrument with individual lifting heads now offers the flexibility to run each station independently for carrying out different textile tests simultaneously.

These developments will be showcased at this year’s ITMA Asia + CITME exhibition, which takes place in Singapore from October 28-31.

BTMA CEO Jason Kent said: “These BTMA companies continue to push the boundaries of what’s possible in the area of textile testing. They are each making solid contributions to the quality and performance properties of today’s textile products, and just as importantly, enabling manufacturers to prove their claims.”