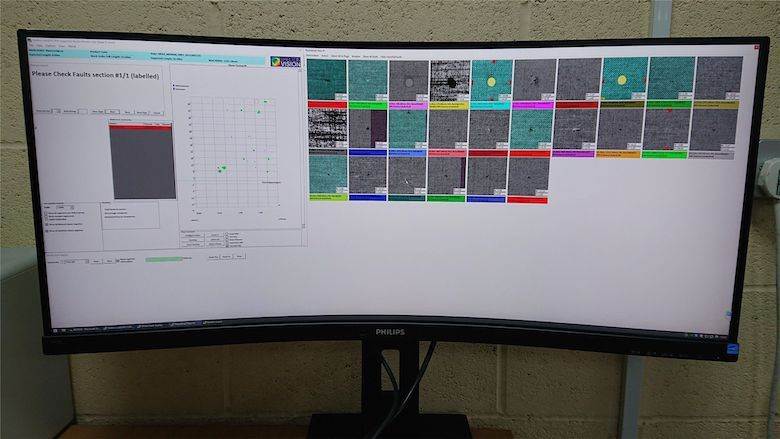

AI vision systems spot 100-plus defects in real time

UK manufacturer Shelton Vision, a developer of machine vision systems for textiles, has built technology capable of identifying 100-plus fabric defects in real time from a “much smaller” number of image inputs, using a combination of machine learning and artificial intelligence (AI) grading software.

The company, a British Textile Machinery Association (BTMA) member, has already sold several systems to industry partners, it said.

Each can be tailored to an individual company, group or product value chain, Shelton Vision added, to help resolve common issues including differing quality standards and inconsistencies in classifying defects across geographies, plus general fabric variations from raw material through texture and finish.

Operatives can set up the vision system with as little as 30-50 quality images per defect type, opting to populate the AI engine with data from the machine itself or using their own images, such as from a smartphone camera.

Periodic data cleaning can also help users resolve conflicts and correct misnamed images.

“There is a global drift away from the type of activity that [manual] fabric inspection requires, making Shelton Vision’s technology increasingly valuable to forward-looking mills,” commented BTMA chief executive, Jason Kent.

Shelton Vision’s intelligent fabric inspection systems have been shown to outperform manual processes in “speed, accuracy and consistency”, Mr Kent went on to say.

Image: Shelton Vision.