Automated pre-processing device for post-consumer clothing

04/07/2025

Clothing is first placed on a conveyor belt and passes under an imaging station where three specialised cameras generate a high-resolution, multi-dimensional map of the garment. This map makes it possible to identify fibre composition. A combination of AI and machine vision locates and removes any non-recyclable element from the item of clothing.

To identify the location of the unwanted elements on garments, associate professor Abu Islam and engineer Sri Priya Das developed vision-guided algorithms that identify logos, collars and cuffs. The data is then communicated to an automated laser-cutting system that removes those elements without damaging reusable material. Once cut, the garment proceeds to a robotic sorting gantry, which places the recyclable material into separate bins depending on composition. The prototype is said to be able to process an item of clothing in 10 seconds.

“It’s not going to solve the world’s textile waste problem, but it’s a step toward a more circular economy,” commented program manager Mark Walluk. “Today, recyclers prefer post-industrial fabrics because of their predictable material properties. We’re working to advance beyond that step by transforming post-consumer clothing into high-quality, reliable feedstock also.”

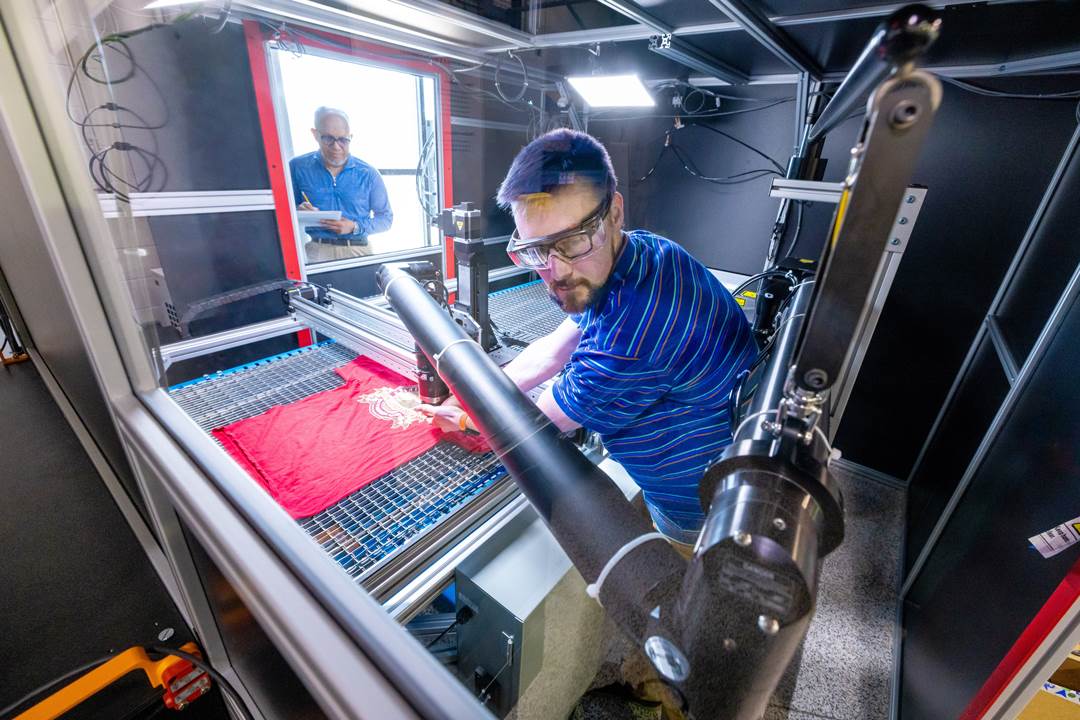

Photo, courtesy of RIT, shows senior staff mechanical engineer Ryan Parsons, right, calibrating a laser safety tube for an AI-guided robotic arm and associate research professor Abu Islam, back left.