‘Significant advancements’ lead to 3D printed midsole from New Balance

23/11/2015

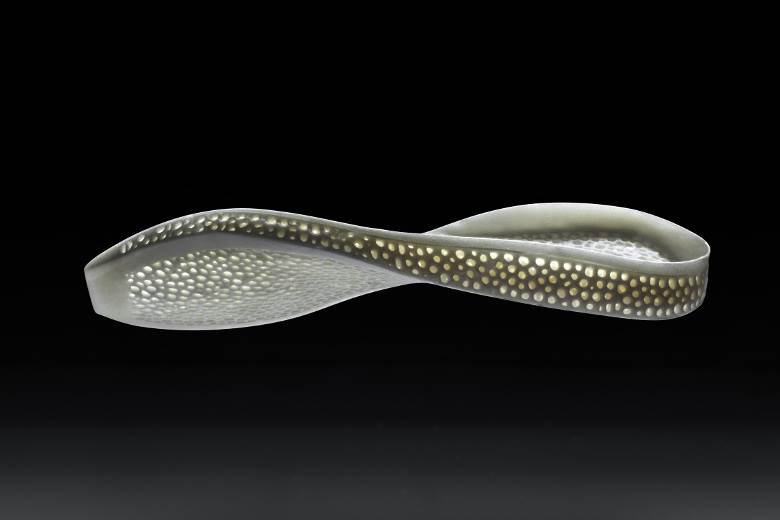

It makes use of 3D Systems’ new elastomeric powder, DuraForm Flex TPU, which it says balances flexibility, strength, weight and durability.

It is produced by selective laser sintering (SLS), a process that converts new powder materials into solid cross-sections, layer by layer, using a laser.

“This project represents an unprecedented technical collaboration in footwear,” Sean Murphy, New Balance’s manager of innovation and engineering. “To deliver this level of performance with a 3D printed component, we paired experts in running and biomechanics with leaders in plastics engineering, material development and generative design. These are the types of collaborations that will drive footwear design and manufacturing in the future.”

The limited edition running shoe will launch in Boston in April 2016 and then in selected stores around the world.

In 2013, New Balance launched customised 3D printed spike plates.

Adidas unveiled its 3D printed midsole concept last month.