Nike praises advances in 3D-printed baseball cleat

06/07/2017

Its engineers gathered data based on his foot and body movements to refine the plate structure.

The US company first used computational design and 3D printing in the 2013 launch Nike Vapor Laser Talon. “The athletes did exceptionally well, which proved that these plates worked,” said Roger Chen, a director in the digital innovation team.

The team took knowledge to inform spikes for the 2016 Rio games. “With the extensive research from the Nike Sports Research Lab, we’re able to take athlete data into our computational design process to dictate stiffness and other performance structures at a level of precision we couldn’t do before,” says Chen.

“Though very different from baseball, what we learned from each of the other sports directly influenced how we built Trout’s latest cleat. Specifically, the new cellular language that we created for the track and field plates had the benefits of additional stiffness, but were also lightweight and could be tuned for desired performance.”

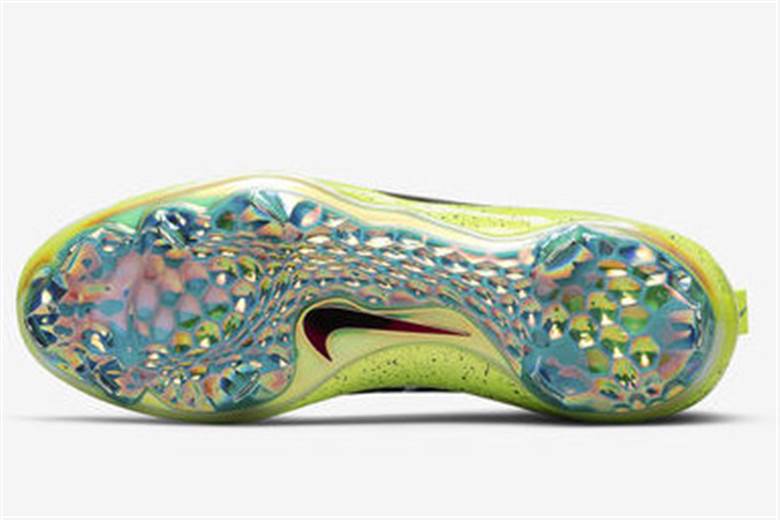

The team also did finite element analysis testing, which is a traction test that involves simulating the cleat's performance. “We look at the forces driven by him, and then we try to simulate that digitally so that we can tune the traction and the actual performance of the plates,” explains Chen.

“Using Trout’s foot scans, movements and pressure maps allows us to go in and precisely tune the stiffness, flexibility and structures for performance,” explains Chen.

For example, the hexagonal structures were compressed in areas requiring stiffness and were relaxed in areas requiring flexibility.

Hexagonal Zoom Air units were placed strategically to distribute pressure as well as provide comfort.