Nike homes in on disassembly on its journey towards circularity

04/05/2022

Nike has been embracing circular design principles for several years, outlined in the Nike 2019 Circular Design Guide, an open-source workbook to share learnings and insights with the design community.

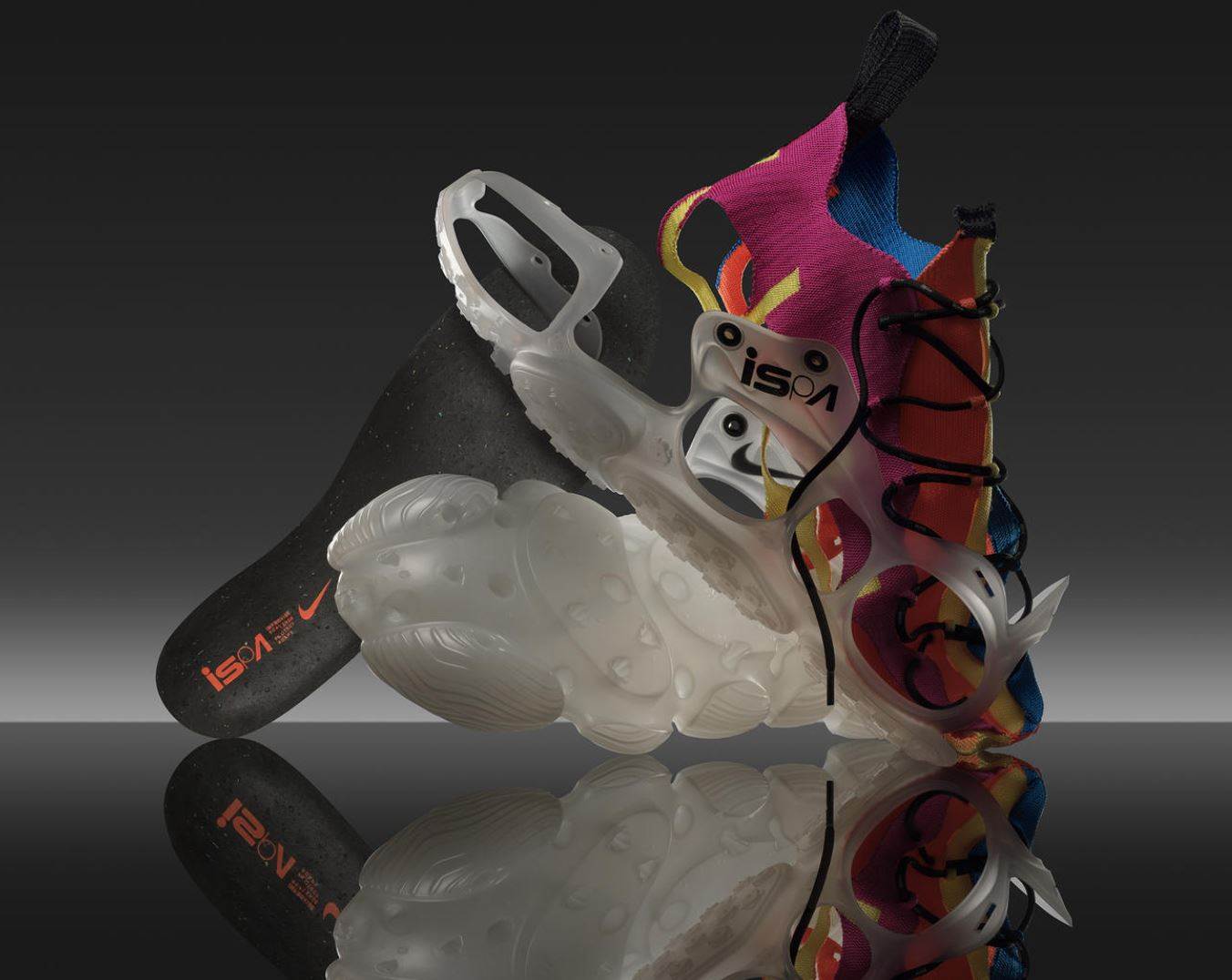

This season, the ISPA team considered the circular design principle of “disassembly”. Traditionally, designers use glue and other bonding elements to make the shoe durable, but that makes a shoe difficult to disassemble and recycle.

Recycling shoes usually requires shredding, an energy-intensive process that limits how the recycled materials can be used. Creating a shoe that can be taken apart would reduce the carbon footprint of the product and open up new possibilities for its lifecycle.

Darryl Matthews, vice-president of catalyst footwear product design, said: “Designed in partnership with engineering, digital product creation and development, these shoes are completely informed by method of make — it really is a case of form following function.

“Our hope is that these ideas and aesthetics become normalised, accelerating our ability to imagine how shoes will continue to evolve in the future.”

Nike is proud to participate in “Plastic: Remaking Our World,” an exhibition at Germany’s Vitra Design Museum, one of the world’s leading design institutions, from March 26 to September 4, 2022. The exhibit highlights the exploration of design and evolutionary journey behind the ISPA Link Axis.

Nike is also building partnerships to grow its recycling capabilities, and is investing in product take-back consumer programmes across the world that will help grow its ability to repurpose end-of-life products.

Image: The Link Axis is made from a 100% recycled polyester Flyknit upper and its recycled TPU tooling is made from waste airbag material.