Hyosung and Loop bet on T2T

18/09/2025

Loop’s technology reverts polyester back into DMT and Meg (instead of the more common PTA and MEG). This is a deliberate choice, Mr Essaddam said as it avoided the complications of filtering PTA.

The company has been operating a plant in Terrebonne, Québec, for the past five years. “We have trialled 2,500 different types of feedstock there,” he said. Loop is currently building a large scale facility in India with a local partner, Ester, a polyester producer. This facility should be operational in 2028 and will have a capacity of 70,000 tonnes. It will have close access to feedstock, post-industrial and post-consumer, as well as a production line for rPET. Plans for a future facility in Europe are also in the works.

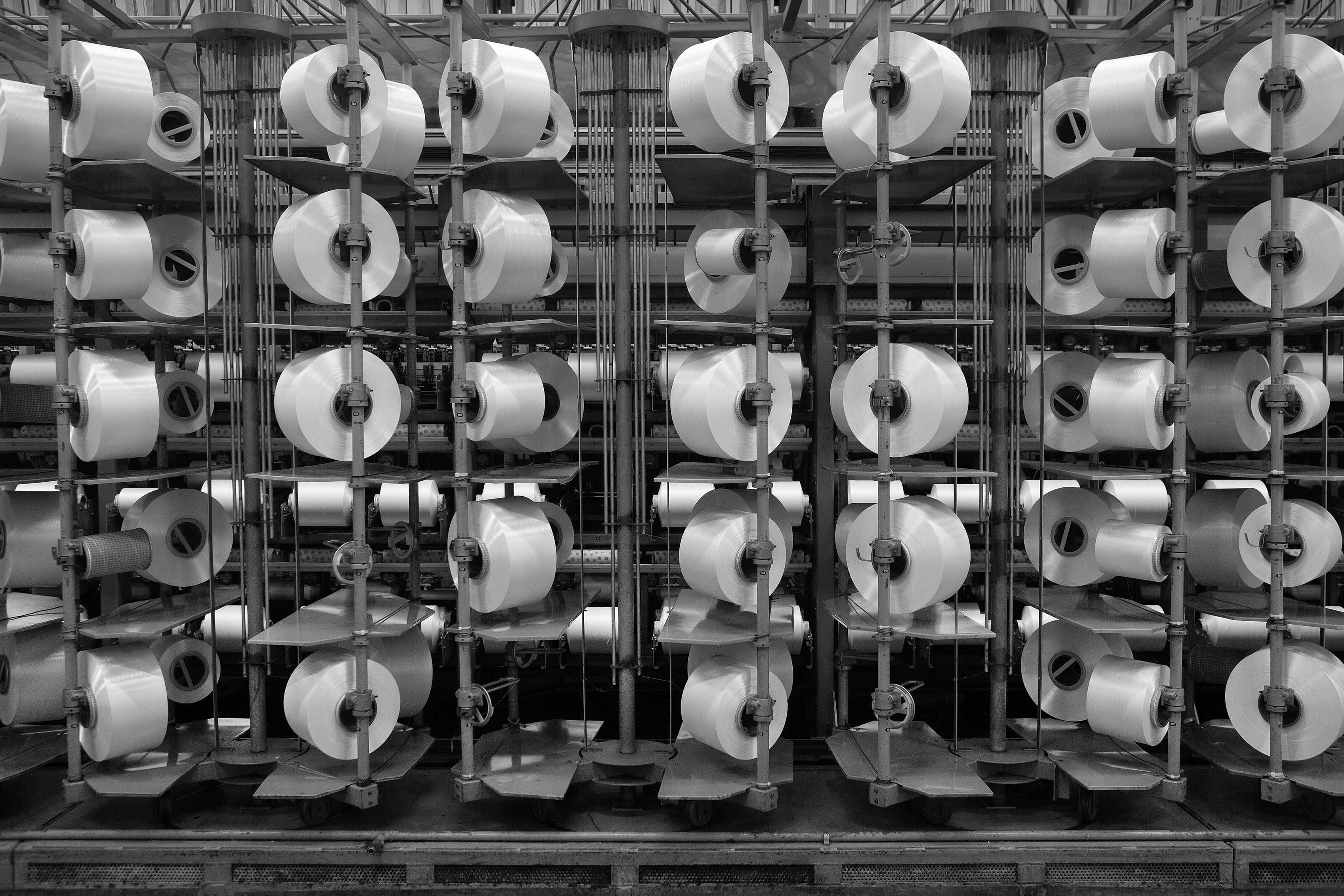

Image courtesy of Loop Industries / Hyosung