Bluesign on the future of sustainable chemicals

08/02/2021

Switzerland-headquartered Bluesign Technologies delivered a workshop presentation on the topic of sustainable chemicals (“What next?”) during the final day of ISPO Munich Online, which ran between February 1-5, 2021.

The presenter, Dr Thomas Schaefer, focused his presentation on the environmental protection aspect to sustainability and made special mention of what he considered to be “the future” - that is, the allocation of a water, energy or greenhouse gas emission footprint to a specific textile auxiliary, dyestuff or chemical product.Dr Schaefer described how system boundaries must be defined well for this to work, however and said that, at the moment, the data for this is “not really given well”.

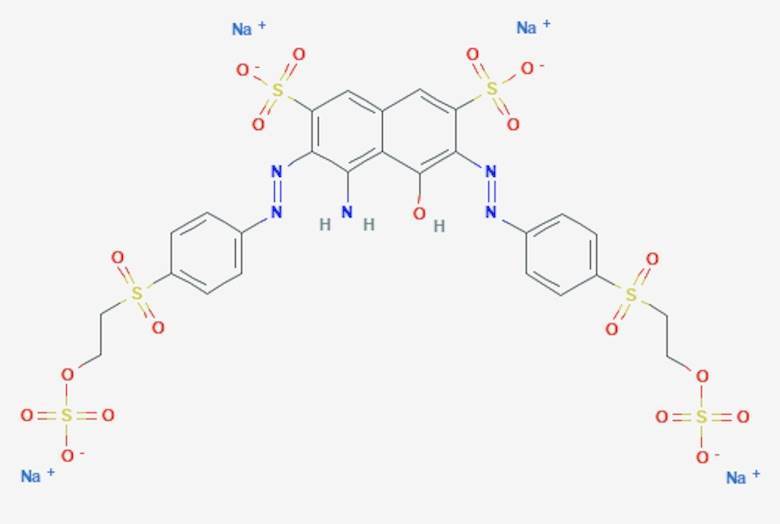

Employing the compound chemical Reactive Black 5 (pictured), used to dye denim black, as an illustration, he showed how many raw materials, intermediates and reaction steps are necessary to achieve the chemical dye. Dr Schaefer said that it would therefore be “difficult” to go back to “complex” production chains in order to allocate greenhouse gas emissions, for instance, to a particular chemistry.

What sustainably-minded parties can do, however, is seek out “clean factories”, such as production sites with “appropriate” environmental and occupational health and safety performance, plus those with “optimised” resource efficiency (ie, less emissions) and sites that follow a “responsible care” philosophy and demonstrate “appropriate” product stewardship knowledge.

A key takeaway from the presentation, Dr Shaefer pointed out, was not to get stuck in “Manufacturing Restricted Substances List (MRSL) thinking”. Meaning, to not “only” think in terms of less hazardous chemicals or less impurities, but rather to also pay closer attention to bio-based, renewable or plant-based raw materials from more sustainable sources.

He suggested looking into chemicals made from recycled raw materials, chemicals with less greenhouse gas emissions recorded during the production process and chemicals which save energy and water at the textile finishing stage.

When asked if by an ISPO participant if using chemicals which are “only” bio-based to a certain degree was not “pure greenwashing”, Dr Shaefer suggested that providing consumers with a “percentage” of bio-based chemicals was better than “only using crude oil”.

He cautioned participants not to resort to “black-and-white thinking” when considering sustainable chemicals.

Image shows the two-dimensional structure of Reactive Black 5. Credit: National Center for Biotechnology Information (USA)